Plasma-Injection Module for Scramjet/Ramjet/Turbojet Applications

Tech ID: 20-010

Inventor: Dr. Sergey Leonov

Date added: August 22, 2019

Technology Summary

Efforts to understand and develop effective plasma-assisted combustion in gas turbine engines have been underway for 20+ years. To date, no practical devices have yet been developed that provide:

- reliable ignition,

- appropriate mixing intensification,

- suitable flame stabilization,

- enhancement of combustion completeness, and

- satisfactory pollution control.

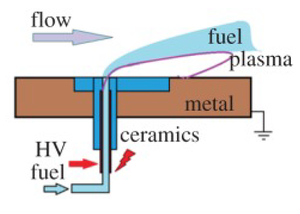

The University of Notre Dame has recently developed a plasma-injection module (PIM) that produces extended filamentary plasma that become entrained in the fuel-air mixing layer and thereby extended by the fuel-injection flow, penetrate into the main airflow, and then terminate far downstream. Validating experiments have been performed in the supersonic blow-down wind tunnel SBR-50 at the University of Notre Dame. In recent tests, the Quasi-DC discharge was employed for fuel ignition and flameholding in supersonic airflows; this type of electrical discharge is considered beneficial compared to plasma torches and less powerful discharges such as Dielectric Barrier Discharges. Supplied by a DC voltage waveform, this discharge demonstrates an oscillatory pattern of its dynamics, significantly affecting flow structure and mixing processes. Thus, proper operation of a Q-DC discharge in ND’s PIM configuration can be realized in high-speed flow in a wide range of gas density/pressure due to a strong coupling of the plasma to the flowing gas. The second generation of PIM demonstrated even higher performance due to application the magnetic-induced active rotation of the plasma filaments.

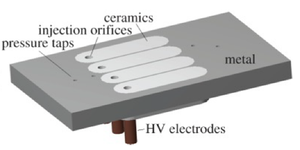

Figure 1. a) Operational concept of PIMs

b) Schematics of the PIM assembly

Specific benefits of ND’s revolutionary PIM include:

- long plasma filament located in the fuel-oxidizer mixing layer; which provides

- significantly longer times for plasma - fuel interaction;

- higher local power deposition at local gas temperatures up to 6kK;

- extremely short ignition / reignition time.

Further, the PIM is made of refractory materials, which permit operation in a harsh environment, and the PIMs are flush-mounted on the combustor wall, thus eliminating any mechanical disturbance of the flowfield. Finally, electronic operation of the PIMs allows their implementation in active close-loop control systems.

Technology Readiness Status

TRL 4 Validation in laboratory environment.

Publication

“Electrically Driven Supersonic Combustion”, Energies 2018, 11, 1733; doi:10.3390/en11071733

Available for licensing and research collaboration.

Contact

Richard Cox

574.631.5158